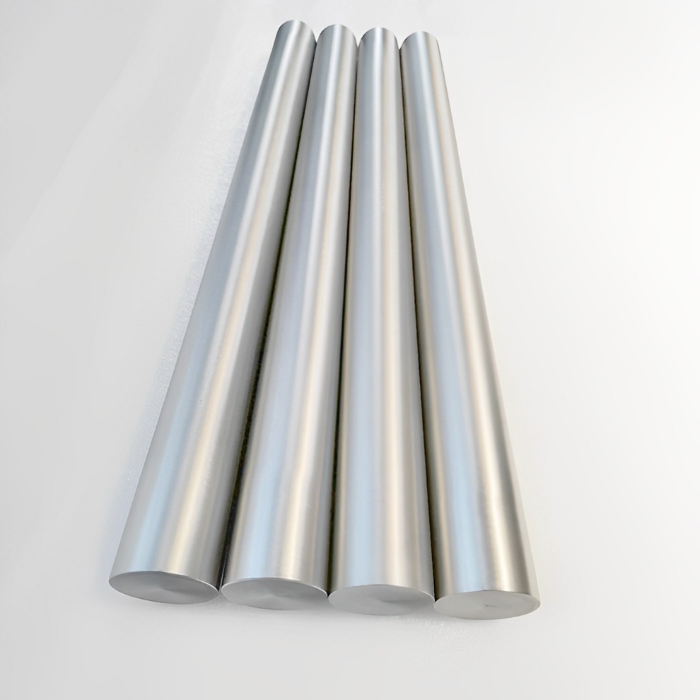

Ikhwalithi ephezulu ye-TZM Molybdenum Alloy Rod

Uhlobo nosayizi

I-TZM Alloy rod ingase futhi ibizwe ngokuthi: TZM molybdenum alloy rod, titanium-zirconium-molybdenum alloy rod.

| Igama lento | I-TZM Alloy Rod |

| Okubalulekile | I-TZM Molybdenum |

| Ukucaciswa | I-ASTM B387, UHLOBO 364 |

| Usayizi | 4.0mm-100mm ububanzi x <2000mm L |

| Inqubo | Ukudweba, ukunyakazisa |

| Ubuso | I-Black oxide, ihlanzwe ngamakhemikhali, Qeda ukujika, Ukugaya |

Futhi singahlinzeka ngezingxenye zomshini ze-TZM Alloy ngomdwebo ngamunye.

Ukwakhiwa Kwekhemikhali kwe-TZM

Izingxenye Eziyinhloko: Ti: 0.4-0.55%, Zr: 0.06-0.12%, C: 0.01-0.04%

| Abanye | O | Al | Fe | Mg | Ni | Si | N | Mo |

| Okuqukethwe (wt, %) | ≤0.03 | ≤0.01 | ≤0.002 | ≤0.002 | ≤0.002 | ≤0.002 | ≤0.002 | U-Bal. |

Izinzuzo ze-TZM uma ziqhathaniswa ne-molybdenum emsulwa

- Amandla okubamba angaphezu kuka-1100°C cishe aphindwe kabili kunalawo e-molybdenum engahlanganisiwe

- Ukumelana nokukhasa okungcono

- Izinga lokushisa elingaphezulu le-recrystallization

- Izakhiwo ezingcono zokushisela.

Izici

- Ukuminyana:≥10.05g/cm3.

- Amandla okuqina:≥735MPa.

- Amandla okukhiqiza:≥685MPa.

- Ubude:≥10%.

- Ukuqina:I-HV240-280.

Izinhlelo zokusebenza

I-TZM ibiza cishe u-25% ngaphezu kwe-molybdenum ehlanzekile futhi ibiza kuphela ngo-5-10% ngaphezulu emshinini.Kuzinhlelo zokusebenza zamandla aphezulu njengama-rocket nozzles, izakhi zesithando somlilo, kanye ne-forging dies, kungakufanelekela ukuhluka kwezindleko.

Bhala umyalezo wakho lapha futhi usithumelele wona