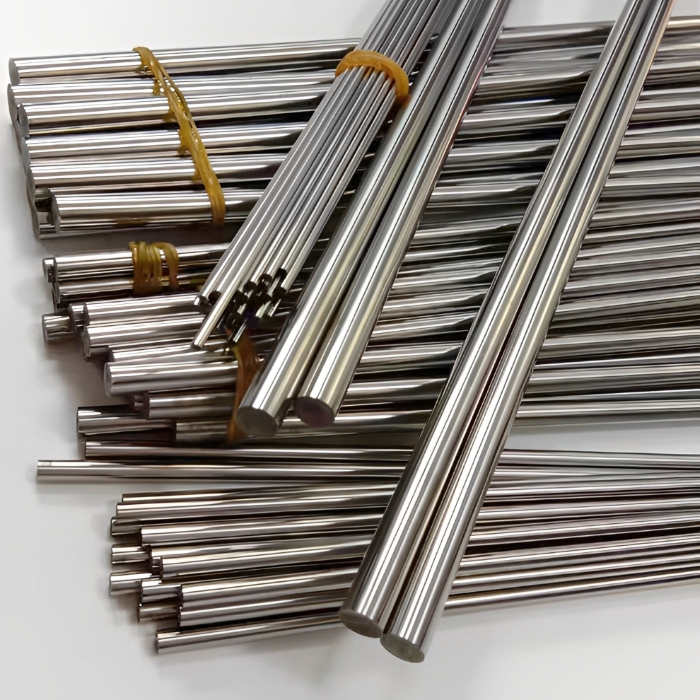

I-High Temperature ye-Molybdenum Lanthanum (MoLa) I-Alloy Rod

Uhlobo nosayizi

- Okubalulekile:I-Molybdenum Lanthanum Alloy, i-La2O3: 0.3~0.7%

- Ubukhulu:ububanzi (4.0mm-100mm) x ubude (<2000mm)

- Inqubo:Ukudweba, ukunyakazisa

- Ubuso:Imnyama, ihlanzwe ngamakhemikhali, Iyagaya

Izici

1. Ukuminyana kwezinduku zethu ze-molybdenum lanthanum kusuka ku-9.8g/cm3kufika ku-10.1g/cm3;I-diameter encane, ukuminyana okuphezulu.

2. I-Molybdenum lanthanum rod inezici ezinobunzima obuphezulu bokushisa, ukuguquguquka kwe-thermal okuphezulu, nokunwebeka okuphansi kokushisa kwezinsimbi ezishisayo.

3. Kuyinsimbi esiliva-emhlophe, eqinile, enephuzu lokuncibilika lesishiyagalombili eliphakeme kunawo wonke;

4. Inokwanda okuphansi kokushisisa kwanoma iyiphi insimbi esetshenziswa ukuhweba.

Izinhlelo zokusebenza

- Isetshenziswa ekukhanyeni, idivayisi kagesi vacuum.

- Isetshenziselwa isici se-tube ingxenye yepayipi le-cathode-ray, idivayisi ye-semiconductor yamandla.

- Isetshenziselwa ukukhiqiza amathuluzi okukhiqiza ingilazi kanye ne-glass fiber.

- Isetshenziselwa ukukhiqiza ingxenye yangaphakathi kumalambu okukhanya, isivikelo sokushisa esiphezulu, i-annealing Filament ne-Electrode, isitsha sokushisa okuphezulu kanye nengxenye ku-microwave magnetron.

Izinduku ze-Molybdenum lanthanum zisetshenziswa kabanzi ekushiseni izakhi ezithandweni zokushisa okuphezulu, ama-electrodes, izikulufu, ama-rabbles embonini yokuncibilikisa umhlaba engavamile, ama-electrode okushisa embonini yengilazi nokusekelwa kwezibani embonini yokukhanyisa, njll.