I-Molybdenum Lanthanum (MoLa) Alloy Sheets

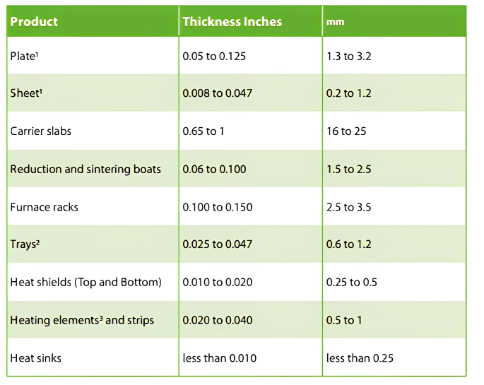

Uhlobo nosayizi

Izici

0.3 wt.% ILanthana

Ithathwa esikhundleni se-molybdenum emsulwa, kodwa ngempilo ende ngenxa yokukhula kwayo ukumelana nokukhasa

Ukonakala okuphezulu kwamashidi amancane;ukugoba kuyefana kungakhathaliseki, uma ukugoba kwenziwa ngezikhombisi-ndlela ze-longitudinal noma eziphambene

0.6 wt.% ILanthana

Izinga elijwayelekile le-doping embonini yesithando somlilo, edume kakhulu

Ihlanganisa amandla okushisa aphezulu amukelwa kabanzi nokumelana nokukhasa - kubhekwa njengento "engcono kakhulu".

Ukonakala okuphezulu kwamashidi amancane;ukugoba kuyefana kungakhathaliseki, uma ukugoba kwenziwa ngezikhombisi-ndlela ze-longitudinal noma eziphambene

1.1 wt.% ILanthana

Ukumelana ne-warpage okuqinile

Izici zamandla aphezulu

Ibonisa ukumelana okuphezulu kakhulu kwawo wonke amabanga anikezwayo

Izicelo zezingxenye ezakhiwe zidinga umjikelezo we-aneal owenziwe kabusha

Izinhlelo zokusebenza

Ipuleti le-Molybdenum lanthanum alloy lisetshenziselwa ukukhiqiza ama-electrode e-tungsten ne-molybdenum, izakhi zokushisa, isivikelo sokushisa, isikebhe esine-sintered, ipuleti eligoqiwe, ipuleti eliphansi, i-sputtering target, i-electronics kanye ne-crucible yokuvala i-vacuum.I-La2O3 iqukethwe kupuleti le-MoLa ukuze kuvinjelwe ukunyakaza okungalungile kwezinhlamvu ze-molybdenum kanye nokuhlanganisa kabusha isigqi esinensayo ngaphansi kwezinga lokushisa eliphezulu.Ukusebenziseka kwepuleti le-molybdenum lanthanum nempilo yesevisi kuye kwathuthukiswa kakhulu.Ubuso bepuleti ye-MoLa alloy esiyikhiqizayo bushelelezi, alikho izinga, alikho i-lamination, akukho mfantu noma ukungcola.