Vacuum coating molybdenum izikebhe

Incazelo

Izikebhe ze-molybdenum zakhiwa ngokucubungula amashidi e-molybdenum aphezulu.Amapuleti anokuqina okuhle kokufana, futhi angakwazi ukumelana nokuguquguquka futhi kulula ukugoba ngemva kokuvala i-vacuum annealing.

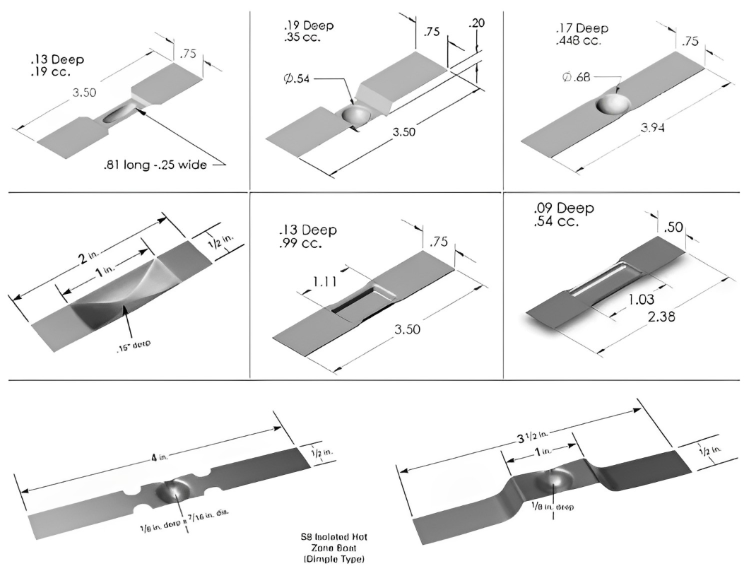

Uhlobo nosayizi

1.Uhlobo lwe-vacuum evaporator eshisayo Isikebhe

2.Ubukhulu besikebhe se-molybdenum

| Igama | Uphawu lwemikhiqizo | Usayizi(mm) | Ubude bomgodi (mm) | Ukujula Komgodi (mm) |

| isikebhe se-molybdenum Usayizi okhethekile ungenziwa ngezifiso! | 210--00PG | 0.2*10*100 | 50 | 2 |

| 215--00PG | 0.2*15*100 | 50 | 7 | |

| 216--03PG | 0.2*25*118 | 80 | 10 | |

| 308--00YG | 0.3*8*100 | 50 | 2 | |

| 310--00PG | 0.3*10*100 | 50 | 2 | |

| 310--01PG | 0.3*10*70 | 40 | 1.8 | |

| 312--00YG | 0.3*12*100 | 50 | 2 | |

| 313--02YG | 0.3*13*49 | 33 | 3.3 | |

| 315--03YG | 0.3*15*100 | 50 | 7 | |

| 316--00PG | 0.3*16*100 | 50 | 4 | |

| 318--03YG | 0.3*18*100 | 40 | 3.5 | |

| 514--00YG | 0.5*14*100 | 50 | 2.6 | |

| 515--00PG | 0.5*15*100 | 50 | 2.6 |

Izici

1. Indawo ephakeme kakhulu yokuncibilika yazo zonke izinsimbi, izici zamakhemikhali ezizinzile

2. Ukumelana kahle kakhulu nokugqwala kwe-electrochemical, okungagqwali kalula emoyeni.

3. Ukugqokwa okuphezulu, Ukuqina okuphezulu, ukuminyana okuphezulu.

4. Amandla amahle okushisa aphezulu.

Izinhlelo zokusebenza

1.I-Metalizing, i-Electron-beam Spraying, i-sinteting annealing ekwehliseni umoya ku-electronics.

2. Izimboni zezempi nezilula

3.Thuthukisa ubude obuncane bocingo noma ukuhwamulisa izinto.

Isikebhe se-3.Molybdenum silungele ukusetshenziswa ezinhlelweni ezincane zokuhwamuka.

Imithombo ye-4.Molybdenum izikebhe isetshenziselwa ukuhwamuka kwe-vacuum yezinto.

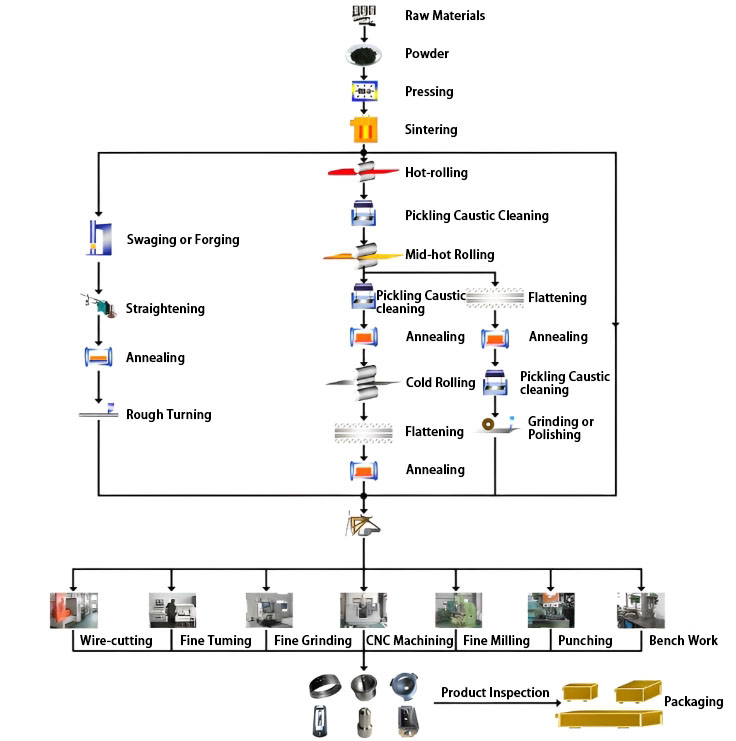

Ubuciko

Impahla eluhlaza:Kusukela ezintweni ezingavuthiwe, sikhetha izinto ezingavuthiwe zekhwalithi ephezulu, ezigqame kakhulu ekuzinzeni nasekuhambisaneni kwemikhiqizo.Khomba izinhlobo ezahlukene zezinto zokusetshenziswa bese umaka inombolo yeqoqo.Futhi iqoqo ngalinye lezinto zokusetshenziswa kufanele lithathwe isampula, lihlolwe futhi ligcinwe kungobo yomlando.Qinisekisa ukulandeleka komkhiqizo ngamunye oqediwe futhi uthuthukise ikhwalithi yomkhiqizo ngokuqhubekayo.

Impushana:Ukulawulwa kwenqubo yokugaya imikhiqizo ye-Zhaolinxin Metal kunembe kakhulu, enezixube eziningana ezinkulu kanye namapulatifomu okudlidliza ukuze kuqinisekiswe ukuthi izinto eziqukethwe ku-pulverizing kanye nenqubo yokuxuba zinganyakaziswa ngokuphelele futhi zisatshalaliswe ngokulinganayo, ukuze kuqinisekiswe ukuhambisana kwenhlangano yangaphakathi. imikhiqizo.

Iyacindezela:Enqubweni yokuhlanganisa impushana, impushana icindezelwa imishini yokucindezela ye-isostatic ukwenza isakhiwo sayo sangaphakathi sifane futhi siminyene.I-Zhaolixin inesikhunta se-batch esiphelele kakhulu, futhi inemishini yokucindezela ye-isostatic ukuhlangabezana nokukhiqizwa kwamaqoqo amakhulu kakhulu emikhiqizo.

I-Sintering:Ku-powder metallurgy, ngemva kokuba i-powder yensimbi ibunjwe ngokucindezela kwe-isostatic, iyashiswa ekushiseni okuphansi kunephuzu lokuncibilika lezingxenye eziyinhloko ukwenza izinhlayiya zixhumeke, ukuze kuthuthukiswe ukusebenza kwemikhiqizo, okubizwa ngokuthi i-sintering.Ngemuva kokwakhiwa kwempushana, umzimba ominyene otholwe ngokufaka i-sintering uhlobo lwe-polycrystalline material.Inqubo ye-sintering ithinta ngokuqondile usayizi wokusanhlamvu, usayizi wembotshana kanye nokuma komngcele wokusanhlamvu nokusatshalaliswa kwe-microstructure, okuyinqubo ewumnyombo we-powder metallurgy.

Ukuqamba:Inqubo yokubumba ingenza izinto zithole ukuminyana okuphezulu, izakhiwo ezingcono zemishini, futhi zibambe iqhaza ekuqiniseni indawo engaphezulu.Ukulawulwa okunembile kwezinga lokucubungula kanye nezinga lokushisa lokubumba lezinto ze-tungsten ne-molybdenum kuyisici esibalulekile ekusebenzeni okuphezulu kwe-Zhaolixin tungsten nezinto ze-molybdenum.Indlela yokucubungula yokusebenzisa umshini wokubumba ukuze kufakwe ingcindezi endaweni engenalutho yensimbi ukuyikhubaza ngokwepulasitiki ukuze kutholwe i-forging enezakhiwo ezithile zemishini, ukwakheka okuthile nosayizi.

Ukuginqika:Inqubo yokugoqa yenza izinto zensimbi zikhiqize ukuguqulwa kwepulasitiki okuqhubekayo ngaphansi kwengcindezi yomqulu ojikelezayo, futhi zithole ukuma kwesigaba esidingekayo kanye nezakhiwo.Ngobuchwepheshe obuthuthukisiwe be-tungsten ne-molybdenum ebandayo futhi eshisayo egoqayo kanye nemishini, kusukela ku-tungsten nensimbi ye-molybdenum engenalutho kuya ekukhiqizeni ucwecwe lwe-tungsten ne-molybdenum, i-Zhaolixinguarante ikunikeza ubuchwepheshe bokukhiqiza obusezingeni eliphezulu kanye nezakhiwo zensimbi eziphakeme.

Ukwelapha Ukushisa:Ngemuva kwenqubo yokubumba nokuginqika, okokusebenza kungaphansi kwenqubo yokwelashwa kokushisa ukuze kuqedwe ngokuphelele ukucindezeleka kwesakhiwo sangaphakathi, kunikeze ukudlala ekusebenzeni kwezinto ezibonakalayo, futhi kwenze okokusebenza kube lula ekushicileleni okulandelayo.I-Zhaolixin inenqwaba yeziko le-vacuum kanye neziko le-hydrogen zokushisa ukushisa ukuze ihlangabezane nokulethwa okusheshayo kwama-oda okukhiqiza ngobuningi.

Ukwenza imishini:Izinto ze-Zhaolixin zithole ukwelashwa okuphelele kokushisa, bese zicutshungulwa zibe osayizi abahlukahlukene abenziwe ngokwezifiso ngomshini womshini onjengokuguqula, ukugaya, ukusika, ukugaya, njll., futhi iqinisekisa ukuthi inhlangano yangaphakathi yezinto ze-tungsten ne-molybdenum iqinile, ayinaso ukucindezeleka. futhi engenamigodi, engahlangabezana nezidingo zamakhasimende.

Ukuqinisekisa ikhwalithi:Ukuhlolwa kwekhwalithi nokulawulwa kuzokwenziwa kusuka ezintweni ezingavuthiwe kanye nesinyathelo ngasinye sokukhiqiza, ukuze kuqinisekiswe njalo ikhwalithi yonke imikhiqizo.Ngesikhathi esifanayo, lapho imikhiqizo eqediwe ilethwa endaweni yokugcina impahla, ukubukeka, ubukhulu kanye nokuhlelwa kwangaphakathi kwezinto kuhlolwa ngamunye ngamunye.Ngakho-ke, ukuzinza nokuvumelana kwemikhiqizo kugqame ikakhulukazi.