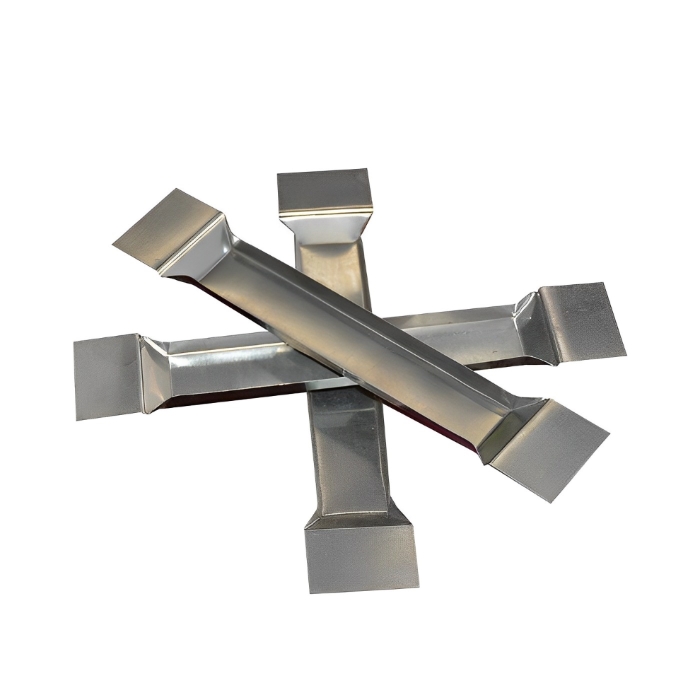

Izikebhe ze-Tungsten ezenziwe ngezifiso ze-vacuum coating

Uhlobo nosayizi

| okuqukethwe | usayizi (mm) | Ubude besikhala (mm) | Ukujula kwesikhala(mm) |

| isikebhe se-tungsten | 0.2*10*100 | 50 | 2 |

| 0.2*15*100 | 50 | 7 | |

| 0.2*25*118 | 80 | 10 | |

| 0.3*10*100 | 50 | 2 | |

| 0.3*12*100 | 50 | 2 | |

| 0.3*15*100 | 50 | 7 | |

| 0.3*18*120 | 70 | 3 | |

| Qaphela: Osayizi abakhethekile bangenziwa ngokwezifiso ngokuya ngezidingo zekhasimende | |||

Izici

Isikebhe se-Tungsten sisetshenziselwa i-vacuum evaporator yezinto ze-granular.Izikebhe ze-Tungsten zingasetshenziswa futhi ukuhwamulisa izintambo ezincane, ezimfushane noma izintambo ezimanzi.Isikebhe sokuhwamuka kwe-Tungsten silungele ukuhlolwa noma umsebenzi wokumodela ohlelweni oluncane lokuhwamuka, njengembiza yensimbi.Njengesitsha esikhethekile nesisebenzayo esimise okwesikebhe, isikebhe se-tungsten sisetshenziswa kakhulu ekufuthazweni kwe-electron ray, sintering and annealing in vacuum coating.

Isikebhe sokuhwamuka kwe-Tungsten sikhiqizwa kulayini okhethekile wokukhiqiza;inkampani yethu ingahlinzeka amakhasimende ngemikhiqizo yekhwalithi ephezulu.Siqinisekisa ukuthi izinto zokusetshenziswa ze-tungsten esizisebenzisayo zimsulwa kakhulu.Ubuchwepheshe obusezingeni eliphezulu nezindlela zokwelapha ezikhethekile zisetshenziswa ekwelapheni okungaphezulu kwemikhiqizo yethu.Inkampani yethu ingakhiqiza isikebhe se-tungsten sokuhwamuka kwevacuum ngokwemidwebo yamakhasimende.

Izinhlelo zokusebenza

Isikebhe se-Tungsten singasetshenziswa embonini yokukhanya, embonini ye-elekthronikhi, embonini yezempi, embonini ye-semiconductor: i-coating, i-sintering precision ceramics, i-capacitor sintering, i-bell jar, i-electron beam spraying.I-X-ray diagnostic target, crucible, heat element, i-X-ray radiation shield, i-sputtering target, i-electrode, i-semiconductor base plate, nengxenye yeshubhu le-electron, i-emission cathode yokuhwamuka kwe-electron beam, kanye ne-cathode ne-anode ye-ion implanter.