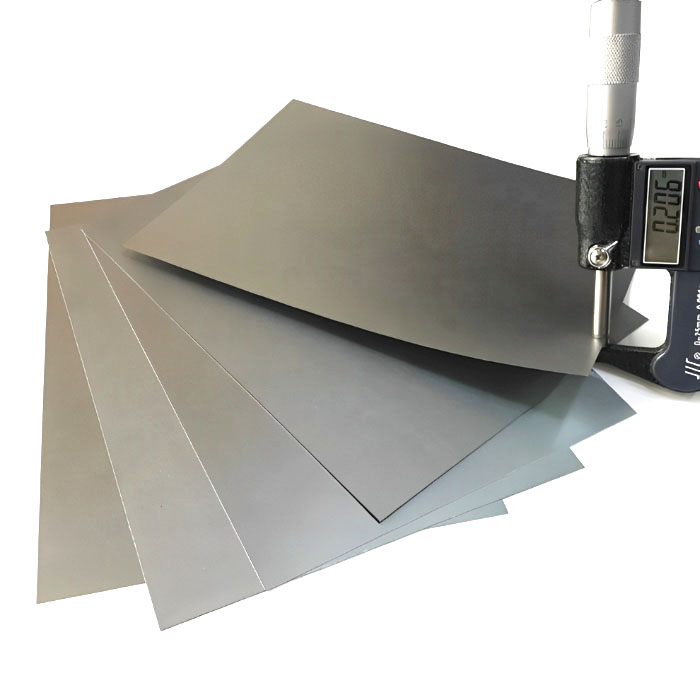

I-Tungsten Heavy Alloy (WNIFE) Rod

Incazelo

Ubuningi be-tungsten heavy alloy rod busukela ku-16.7g/cm3 kuye ku-18.8g/cm3.Ukuqina kwayo kuphakeme kunezinye izinduku.Izinduku ze-Tungsten ezisindayo ze-alloy zinezici zokushisa okuphezulu nokumelana nokugqwala.Ngaphezu kwalokho, ama-tungsten heavy alloy rods anokumelana nokushaqeka okuphezulu kakhulu kanye ne-plasticity yemishini.

Izinduku ze-Tungsten ezisindayo ze-alloy zivame ukusetshenziselwa ukwenza izingxenye zesando, ukuvikela imisebe, izinto zokuvikela ezempi, izinduku zokushisela kanye namamodeli we-extrusion.Futhi ingenye yezinto zokwakha izikhali nezinhlamvu.

Izakhiwo

| I-Density and Hardness Properties, i-ASTM B777 | |||

| Ikilasi | I-Tungsten Purity, % | Ukuminyana, g/cc | Ukuqina, Rockwell"C", max |

| Ikilasi 1 | 90 | 16.85-17.25 | 32 |

| Ikilasi lesi-2 | 92.5 | 17.15-17.85 | 33 |

| Ikilasi lesi-3 | 95 | 17.75-18.35 | 34 |

| Ikilasi lesi-4 | 97 | 18.25-18.85 | 35 |

| Ngokuyinhloko i-tungsten yengeza impushana njengethusi, i-nickel noma insimbi. | |||

| Echanical Properties, ASTM B777 | ||||||

| Ikilasi | I-Tungsten Purity, % | Amandla Okuqina Okugcina | Amandla Esivuno Ku-0.2% Off-set | Elongation,% | ||

| ksi | I-MPa | ksi | I-MPa | |||

| Ikilasi 1 | 90 | 110 nxa | 758 MPa | 75 nxa | 517 MPa | 5% |

| Ikilasi lesi-2 | 92.5 | 110 nxa | 758 MPa | 75 nxa | 517 MPa | 5% |

| Ikilasi lesi-3 | 95 | 105 nxa | 724 MPa | 75 nxa | 517 MPa | 3% |

| Ikilasi lesi-4 | 97 | 100 ksi | 689 MPa | 75 nxa | 517 MPa | 2% |

| Ngokuyinhloko i-tungsten yengeza impushana njengethusi, i-nickel noma insimbi. | ||||||

Izici

Ngaphandle kokuminyana okuphezulu nokumuncwa kwemisebe, izakhiwo eziningi ezibalulekile ezihambisana nobulukhuni obuphezulu nokumelana zisetshenziswe kwinani elikhulu lezinhlelo zokusebenza.Ingxubevange ye-Tungsten esindayo ingeyengxube yensimbi ephikisayo ekwazi ukumelana nokushisa nokuguga ngendlela engavamile.Ingxubevange ye-Tungsten esindayo isetshenziswe ngokuyinhloko ukwenza izingxenye ezidinga ukumelana nokugqoka okuphezulu njengamathuluzi omshini ohlanganisa ama-lathe namadayisi.

Ithola ukuncishiswa okuncane ezicini zayo ngisho namazinga okushisa aphezulu futhi inokumelana okuhle kakhulu kokugqoka.Ngakho-ke, ama-alloys e-Tungsten asetshenziselwa amathuluzi wokwenza imishini anjengama-lathes, imishini yokugaya, njll., nokukhiqiza izingxenye zezimoto ezinjengezinjini, ukuhanjiswa, ukuqondisa, njll., okunomthelela ekwenzeni ngcono ukunemba kwemishini.

Ukwandiswa kwe-thermal ephansi

High conductivity ezishisayo kanye kagesi

Ukumelana ne-arc ephezulu

Ukusetshenziswa okuphansi

Izinhlelo zokusebenza

I-Tungsten heavy alloy inhle kakhulu ezinhlelweni ezidinga ukusebenza okuphezulu ekuphikeleni ukugqwala, ukuminyana, ukusebenziseka kalula, nokuvikela imisebe.Ngakho-ke, lokhu kuyenza ilungele ukusetshenziswa ekwenziweni kwensimbi ethile, izimayini, i-aerospace, nezimboni zezokwelapha.